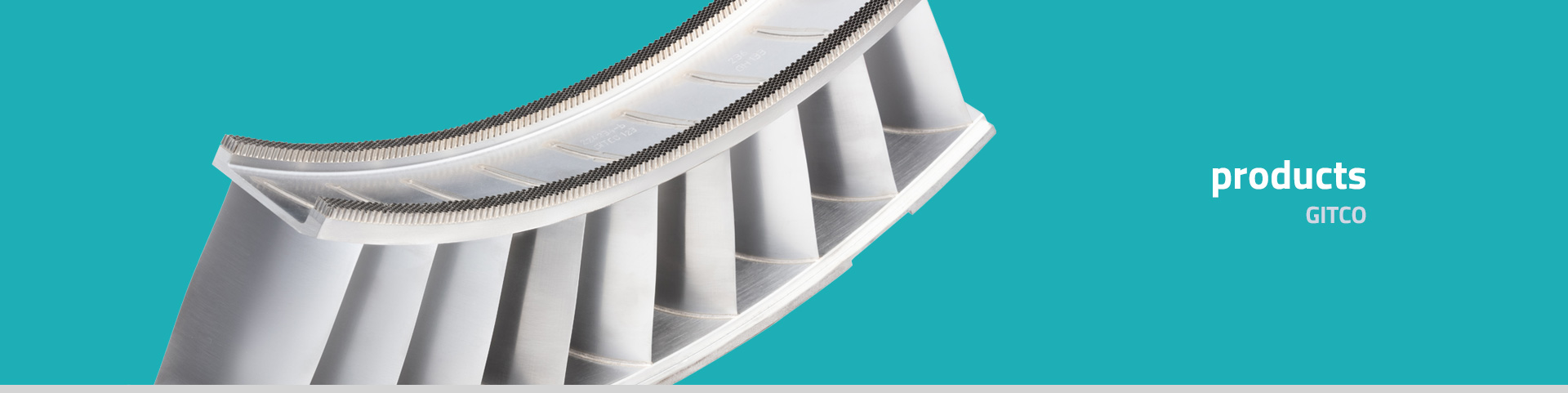

Compressor blades for gas turbines is one of the main products of our company. GITCO can produce different types of compressor rotor blades, stator vanes and inlet guide vanes in stainless-steel, titanium and nickel alloys. In our company, the big blades are produced through machining of forging preforms while the small ones are milled from bars. Our expertise and equipment allow us to manufacture complex shapes of compressor rotor blades and stator vanes from the big stages up to the small ones with excellent quality and competitive price.

We are also able to supply the parts with additional manufacturing operations such as brazing, shot peening, vibro-finishing and coating, where applicable and according to the customer demands. Furthermore, the parts can be supplied as ready-for-assembly on which are performed frequency test, weight moment measurement and calculation of the assembly sequence.

GTICO currently produces turbine blades and vanes in accordance with the following technologies:

• Siemens SGT-600

• Siemens V94.2

• GE Frame 5, 6, 9

We are also capable to produce other turbine blades through reverse engineering.

TURBINE BEARINGS

TURBINE BEARINGS

GITCO specializes in manufacturing of hydrodynamic fluid film bearings for high-performing turbomachinery and rotating equipment in oil & gas, power generation, marine and industrial markets. We currently produce a variety of bearings such as tilt pad journal bearings, tilt pad thrust bearings and combined journal-thrust bearings for gas turbines. Our bearings are made to order and we can offer manufacturing according to supplied drawings or reverse engineering from any sample component.

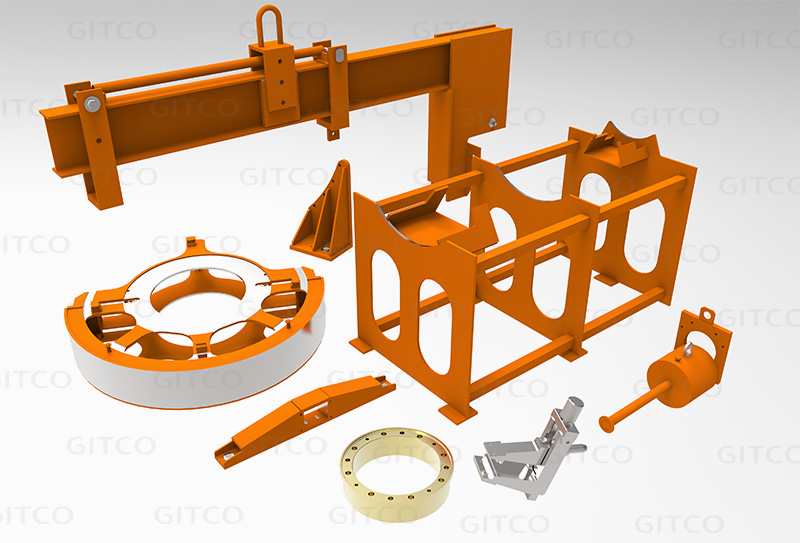

GAS TURBINE PARTS

GAS TURBINE PARTS

In addition to turbine compressor blades and bearings, GITCO produces a large variety of piece parts and components for gas turbines, (more than 1000 types), such as: turbine tie bolts, shims, keys, balance weight, fuel nozzle, fuel manifolds, special tools, guide collar, tension screw, lead through, eccentric shaft, taper pin, sealing rings, lock screw, and etc.

FLEXIBLE METAL EXPANSION JOINTS

FLEXIBLE METAL EXPANSION JOINTS

Metal expansion joints are flexible connections, installed in piping and ducting systems to accommodate expansion and vibration caused by changes in temperature, pressure and/or media. We can provide flexible hose with stainless steel parallel spirals, with outer single or double reinforcement braid wires in AISI 304 or AISI 316 stainless steel, equipped with fittings or flanges end connections, used for conveying fluids in presence of vibrations, high pressures and temperatures.

Thanks to an efficient TIG welding center, we are able to provide metal expansion joints from the size DN 10 to DN 500, for the most sophisticated applications, according to the customer’s drawing or by our design by following the most modern assembly procedures

EXPLOSION-PROOF ELECTRICAL ENCLOSURES

EXPLOSION-PROOF ELECTRICAL ENCLOSURES

GITCO produces a series of explosion-proof electrical enclosures manufactured in either stainless steel or mild steel can be used in hazardous areas. The enclosures are designed and certified by ATEX as increased safety and intrinsically safe enclosures for a wide range of industrial applications in hazardous areas zone 0 and 1 and ambient condition -30°C to + 65°C. These enclosures can be fitted with an arrangement of components or can be supplied empty as component approved for the clients own certification requirements. The enclosures may be employed as:

These enclosures are available in a wide variety of size (more than 80 sizes). Our certified high voltage range of the junction boxes can be used for maximum rated working voltages of 11 kV.

For more details, see the technical data sheet HERE

ELECTRICAL PANELS

ELECTRICAL PANELS

GITCO supplies types of electrical panels used in power generation, oil and gas and related industries. The panel types that we have manufactured include:

All panels manufactured by GITCO are fully inspected by our quality team. GITCO provides all levels of inspections and testing, from simple continuity and leak checks to complete functional tests, calibrations and programming.

GAS TURBINE AUXILIARY SYSTEMS

GAS TURBINE AUXILIARY SYSTEMS

In GITCO, we provide and manufacture to order different auxiliary systems for gas turbines as prototypes or batch runs:

BASE FRAMES

Turbines, compressors and generators are mounted on a base frame to carry its weight, to maintain its alignment and to assist in carrying the dynamic loads which every machine generates.

We specialize in manufacturing all kinds of base frames according to customer’s requirements. In our base frames welding stresses will be removed and the installation interfaces will be machined

ACOUSTIC ENCLOSURES

The Turbine acoustic enclosure comprises of collapsible type Acoustic Wall and Roof Panels assembled on bolted structure. The enclosure will be provided with soundproof doors and glass windows in adequate numbers. To take away the heat built up inside the enclosure, forced ventilation package with ventilation exhaust blower, ventilation intake silencer and ventilation exhaust silencer will be provided. The openings that are required for piping, cables etc., will be acoustically sealed. Provisions for electrical and firefighting system shall also be made.

GITCO is able to provide acoustic enclosures for gas turbines, steam turbines, generators, gas or diesel engines, compressors, pumps in accordance with customer’s demands.

INLET FILTER HOUSE

INTAKE SILENCING SYSTEMS

INTAKE PLENUM

EXHAUST DIFFUSERS / PLENUMS

EXHAUST SILENCING SYSTEMS

TURBINE IGNITION SYSTEMS

GITCO offers low voltage and high-energy igniters for gas turbine engines. Our products is ATEX certified and can satisfy the most rigorous standards to meet customer needs. Flameproof ignition equipment provides special protective measures to avoid accidental combustion in hazardous environments, including flammable gases, vapors and volatile liquids.

Ignition systems for gas turbines consist of three main components: the exciter box, the ignition lead, and the igniter. The exciter box sends high-voltage current to the ignition lead, which transfers the high voltage to the igniter.

TURBINE-COMPRESSOR WASHING SYSTEM

Gas turbine compressors consume approximately 60% of the overall cycle energy during operation. This cycle consumes large quantities of air and although this air is filtered, small quantities of dust, aerosols and water pass through the filters and deposit on the blades. These deposits decrease the air flow of the compressor and the overall performance of the gas turbine.

GITCO’s compressor washing system can be used for gas turbines 14 to 35 mw for either permanent or mobile installation applications. The system can be fitted with an optional wheel kit for mobility on flat concrete type surfaces. The System is designed to be implemented with the relevant nozzle kits and used on the following engines:

Siemens SGT500, Rolls Royce MT30, Siemens SGT600, Siemens SGT700, Siemens SGT750, Siemens SGT800

AUXILIARY SKIDS

We specialize in producing integrated auxiliary skids for rotating machines like turbines, compressors and generators in the power generation and oil & gas industries. The auxiliary skids are made to order and we can offer manufacturing according to supplied drawings and customer’s specifications, codes and rules.

Some of our products are:

• Lube oil system

• seal gas panels

• various gas skids

• pressure vessels

Many of lube oil and gas skids supplied by GITCO are currently in service for IRAN oil and gas industries. Our skilled technical team with good experience of auxiliary equipment, ensures the highest quality in fabrication, test, sales and aftermarket support

STEEL STRUCTURES

STEEL STRUCTURES

Our efficient and qualified welding workshop enables us to supply secondary support structures for power, oil& gas, refineries and chemical industries. We can also manufacture fabricated steel structures for infrastructure projects in bridges, walkways, girders, foot over bridges, boiler support structures, pipe rack structures, chimney structures.